Standards and certifications

What are the 3-a sanitary standards?

The 3-A Sanitary Standards are American standards related to the design and production of equipment intended for contact with food. The aim of the 3-A Sanitary Standards is to protect consumers from potential risks of food contamination. The primary purpose of the 3-A Sanitary Standards is to ensure that all the parts of an equipment are properly cleaned and sanitized in order to avoid any creation of bacterial charge. As part of the equipment, rubber or plastic hoses enter into this type of evaluation and find in the 3-A Sanitary Standards dedicated chapters and testing methods.

Platinum cured silicone hoses are used in many applications in the pharmaceutical industry: in load cells, as connection between tanks, in dosing systems, and many other applications. This widespread diffusion is due to the fact that platinum cured silicone is a high quality polymer with exceptional characteristics of purity.

Chemical characteristics of silicone rubbers

Silicone rubbers (or polysiloxanes) have a chemical structure different from all other elastomers. In fact, their main chain is not made up of carbon atoms but of an alternation of Si (Silicon) and O (Oxygen) atoms. The Si-atoms are then bound to R organic groups. The presence of Si-O bonds, chemically very stable and difficult to attack bonds, provides characteristics of chemical inertness and resistance to high temperatures. R organic chains, on the other hand, give flexibility, low viscosity, and excellent resistance to low temperatures.

For this reason, silicone rubbers are considerably resistant to temperature, chemical agents and oxidation and excellent electrical insulators.

Silicone vulcanizing and platinum cured silicone compounds

The silicon-based compounds are generally simple: in addition to rubber, they contain inorganic fillers, possible pigments, and a vulcanizing agent (peroxide or platinum). In particular, the silicone rubbers which have platinum as cross-linking agent are particularly valuable, because this catalyst produces a cross-linking process with a yield close to 100%. This is the reason why platinum cured silicone is a compound with a high degree of purity, able to withstand the testing requirements of the most restrictive regulations both in the food and in the pharmaceutical or medical industry, and is considered a leading material for these applications.

Applications of platinum cured silicone

Because of its withstanding characteristics, platinum cured silicone is used when it is necessary to avoid any possible risk of contamination. In fact, platinum cured silicone is free from components that can impact the quality of the pharmaceutical product (leachable) or the risk that products of an aggressive chemical nature can somehow extract components that are harmful to the quality of the drug (extractable).

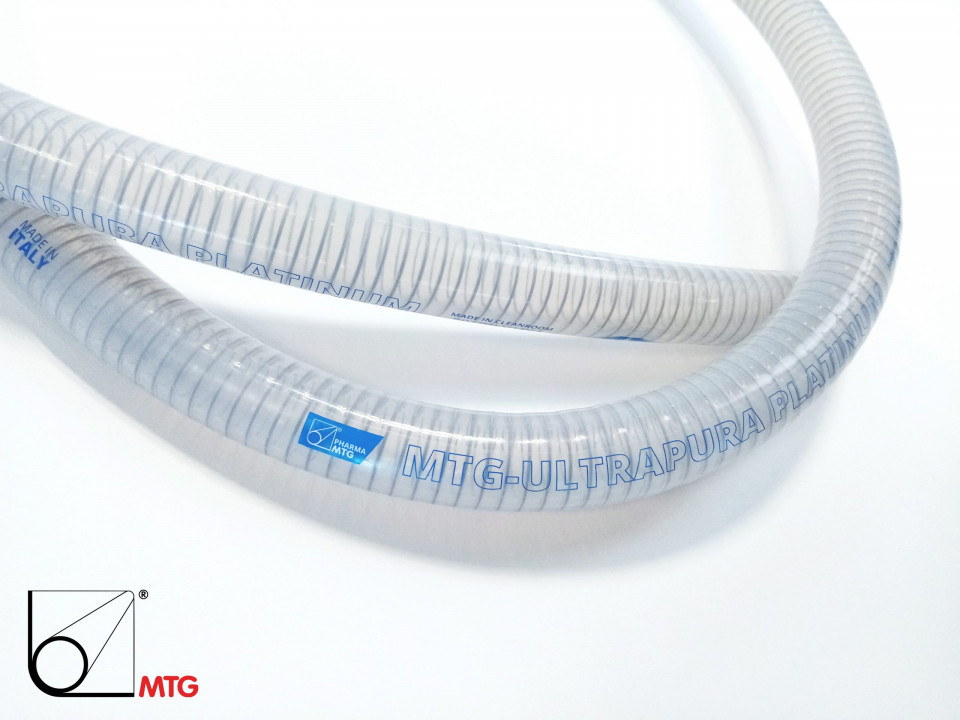

Production in cleanroom of platinum cured silicone

In order to preserve the excellent characteristics of platinum cured silicone, MTG has recently installed and certified according to ISO 14644-1 class 8 a cleanroom manufacturing facility in which the entire production process is carried out: from silicone transformation to the production of the hose, up to its packaging, in order to guarantee a product made according to the most restrictive procedures of cleaning, reproducibility, absence of contaminants.

MTG silicone hoses

The line of MTG silicone hoses includes:

- PHARMATECH: light wall, braided hoses.

- CLEARWAY SD PLATINUM & CLEARWAY HD PLATINUM: wire reinforced hoses.

- Silicone tubing.

The hoses are sterilizable and autoclavable.

Traceability is guaranteed throughout the entire production process. Summary of the validation package is available upon request (including leachable & extractable studies).

To learn more about our platinum cured silicone range of hoses please contact MTG’s Technical Department.